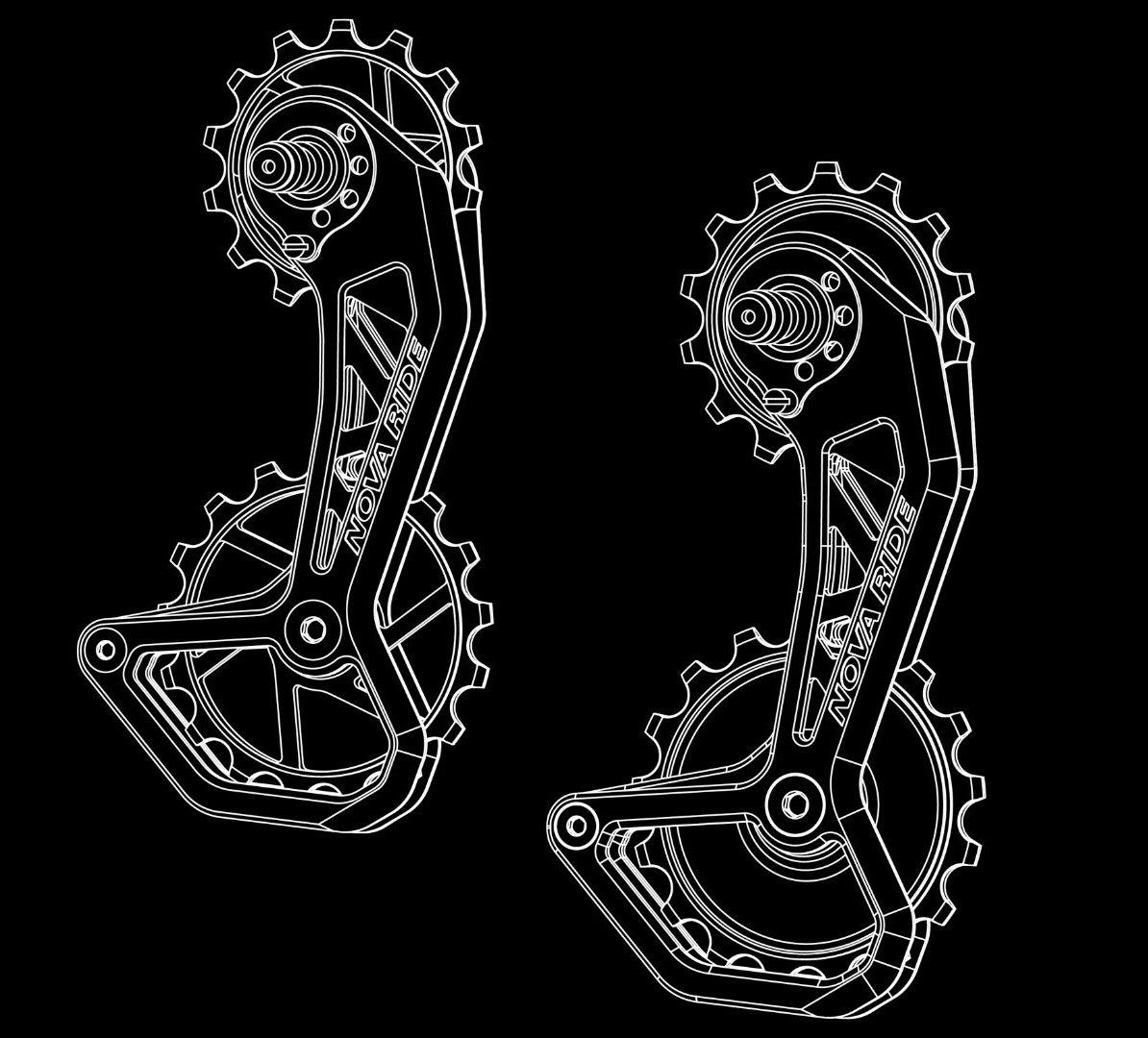

Much more than just an evolution.

In 2020, our oversized Carbon Ceramic Derailleur (CCD) cage was born with a clear ambition: to offer you the most efficient, durable, and best-value system on the market; and that's exactly what we did. For five years, it has proven its effectiveness and reliability on roads and mountain passes around the world, up to the highest race level.

For Nova Ride engineers, each project is a challenge that tirelessly pushes them towards improvement. Today, the team is more than happy to finally reveal in detail its most accomplished transformation: the CCD EVO.

"This evolution is the result of both a thorough analysis of the feedback we have collected from our professional and passionate cycling users, and the continuous enrichment of our design and machining know-how acquired over the last five years.

The main goal is to maintain the functional aspect that made the product successful, while significantly optimizing its performance. This has resulted in in-depth work on reducing weight, improving aerodynamics and increasing the rigidity of the part."

Robin Bourdier, Product Designer at Nova Ride.

Dive into the heart of the development process: from the first sketches to the final design, discover how we created the CCD EVO.

Pushing the limits.

We have deliberately chosen to maintain our high-end materials and manufacturing processes, based on our expertise and their relevance to our use. They allow us to make the most of their potential for a higher level of detail across the entire cage.

However, in order to lighten, stiffen and improve aerodynamics, we have undertaken a complete overhaul of our cage and pulleys. This innovative approach, focused on new geometry and optimized thicknesses, results in significantly increased performance and modernity.

With ever-increasing ambitions and demands, we have created a new design that respects the essence of Nova Ride and fits naturally into its evolution.

Keep the DNA.

This evolution represents much more than a simple update. It is the result of five years of learning and refinement. The CCD EVO takes the qualities that made the original version so successful and transcends them, offering superior performance and design.

Driven by the desire to surpass our existing offerings, the first challenge was to reinvent ourselves while maintaining the Nova Ride heritage and DNA. We took the time needed to explore possibilities and hone the expertise of our design department. It's by testing that we learn.

After many months of development and iterations, the CCD EVO is born, the result of a natural evolution of our ranges. It inherits the distinctive qualities of our CCD, while integrating the design approach of our recent CCD AERO. Like this one, we also used wind tunnel tests at the French AerOptimum test center to meticulously study and validate our design choices.

We were thus able to test the effectiveness of our modifications in real conditions and compare it against a stock cage and our original CCD, which were also tested to collect essential comparison data.

They provided us with a concrete benchmark to objectively assess the performance of our modifications in the wind tunnel. This direct comparison allowed us to precisely identify efficiency gains or losses, understand the real impact of each adjustment, and, consequently, make informed decisions to optimize our final design.

Without this rigorous comparative step, it would have been impossible for us to accurately measure the extent of our progress and achieve the desired level of performance.

The major stages of the development.

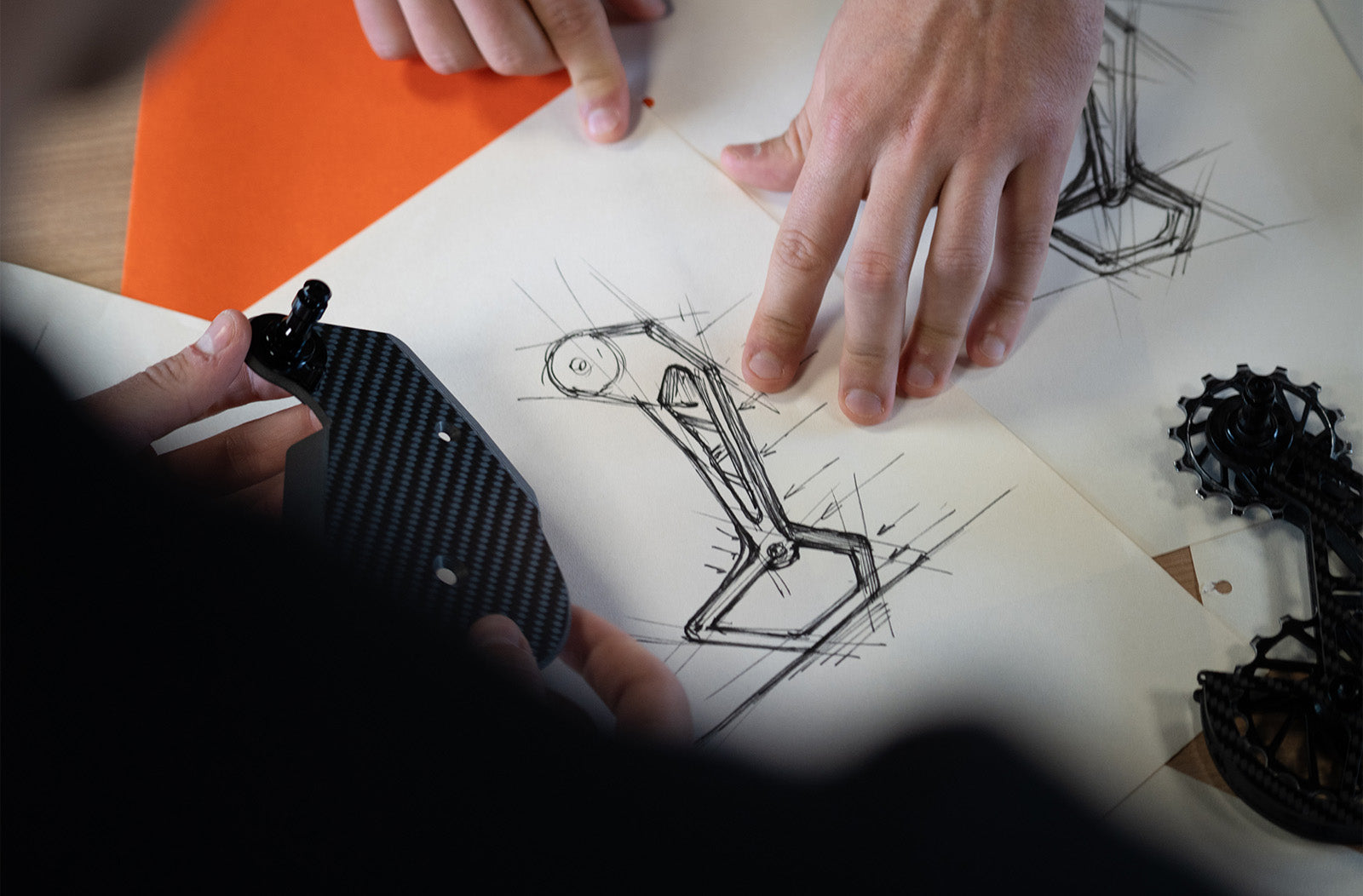

From first sketches to final design

Your expectations and our ambition were the catalyst for the creation of this unique product, with distinctive technical and visual properties.

Grouping ideas

The initial phase of this project consisted of gathering inspirations rooted in our daily lives (cycling, climbing, running, architecture) in order to craft a coherent set of specifications.

The attention to detail and the harmony of forms stemming from these passions guided our approach. This allowed us to sketch out a central concept, laying the solid foundation for this future product.

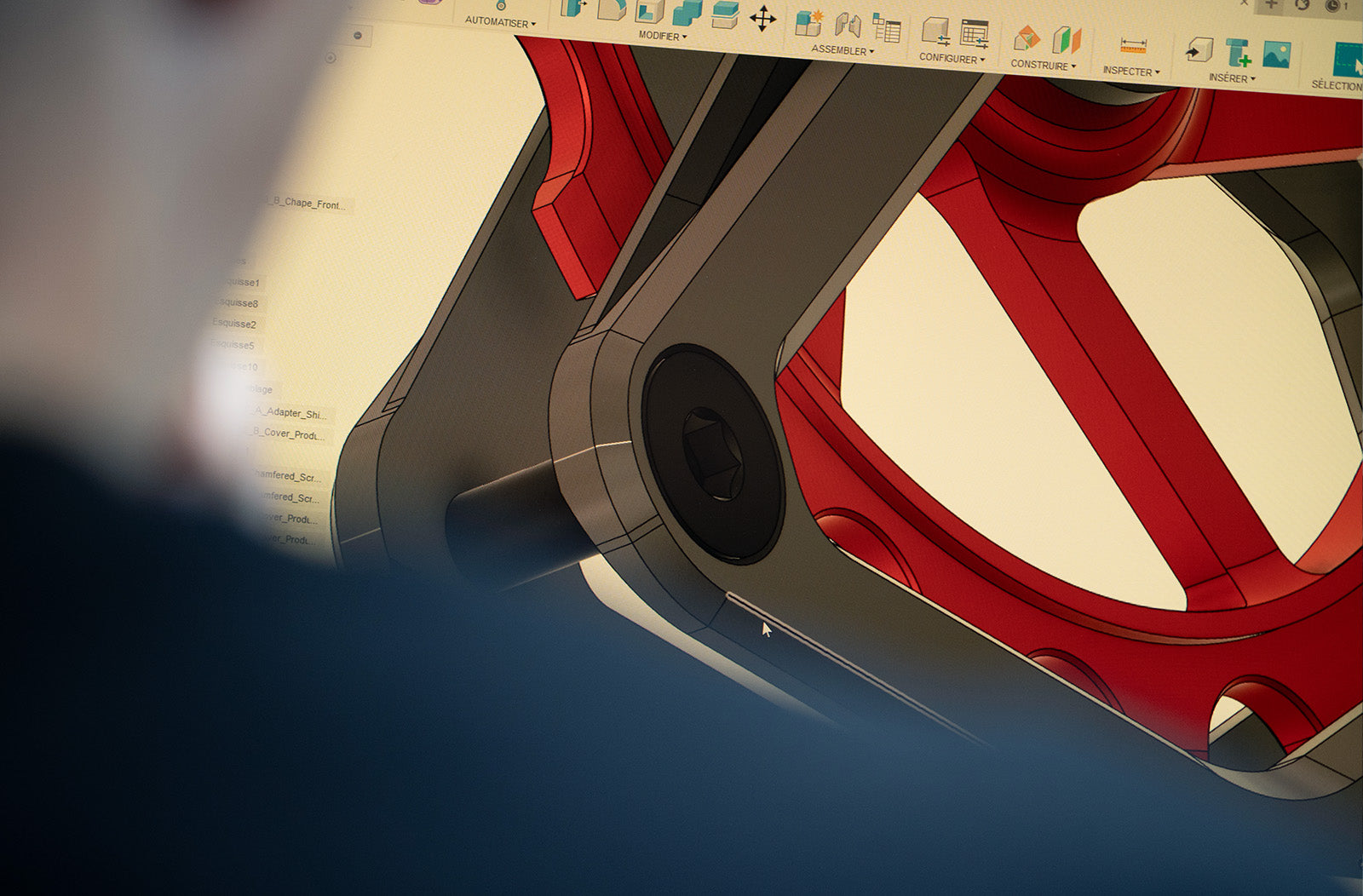

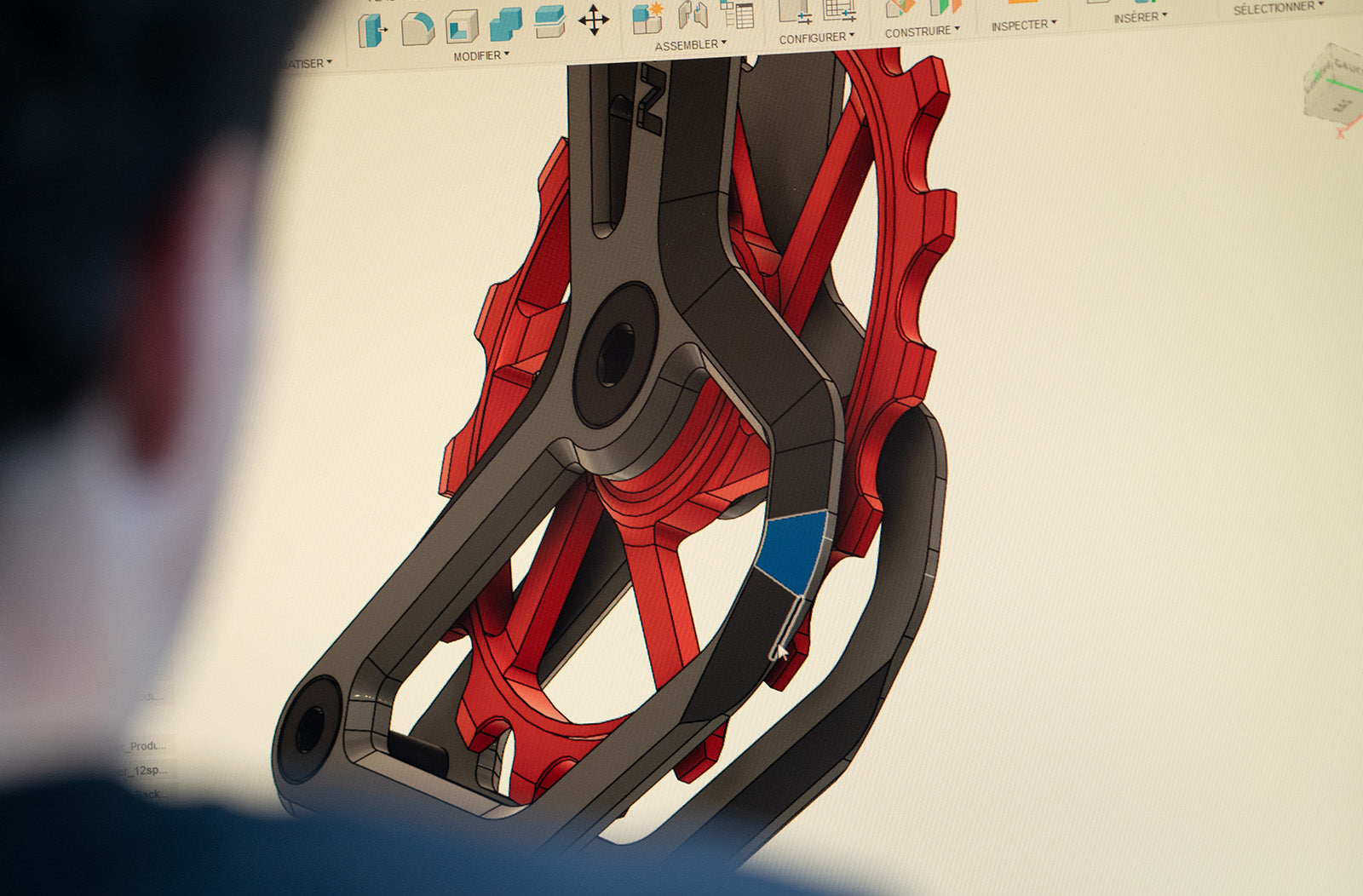

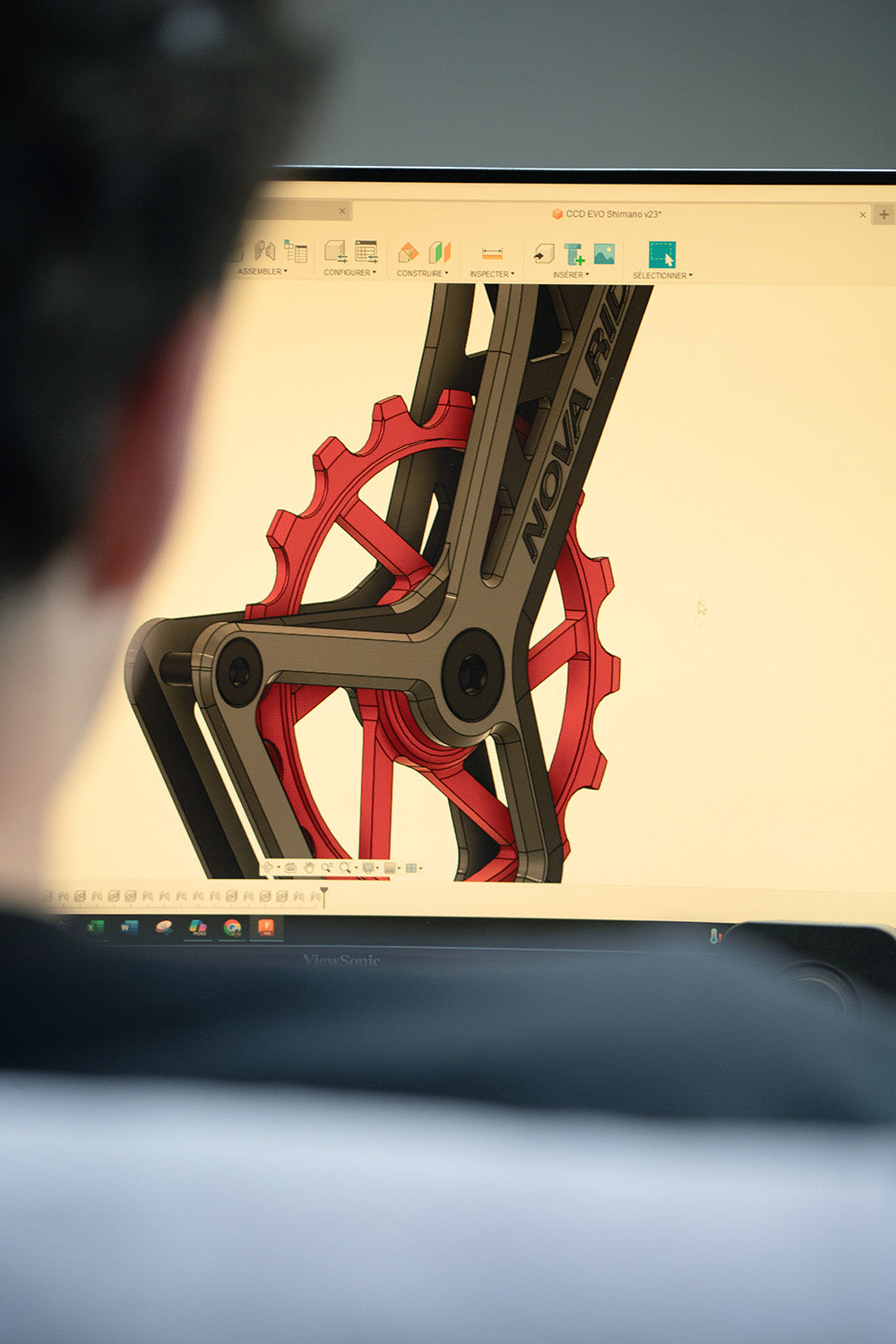

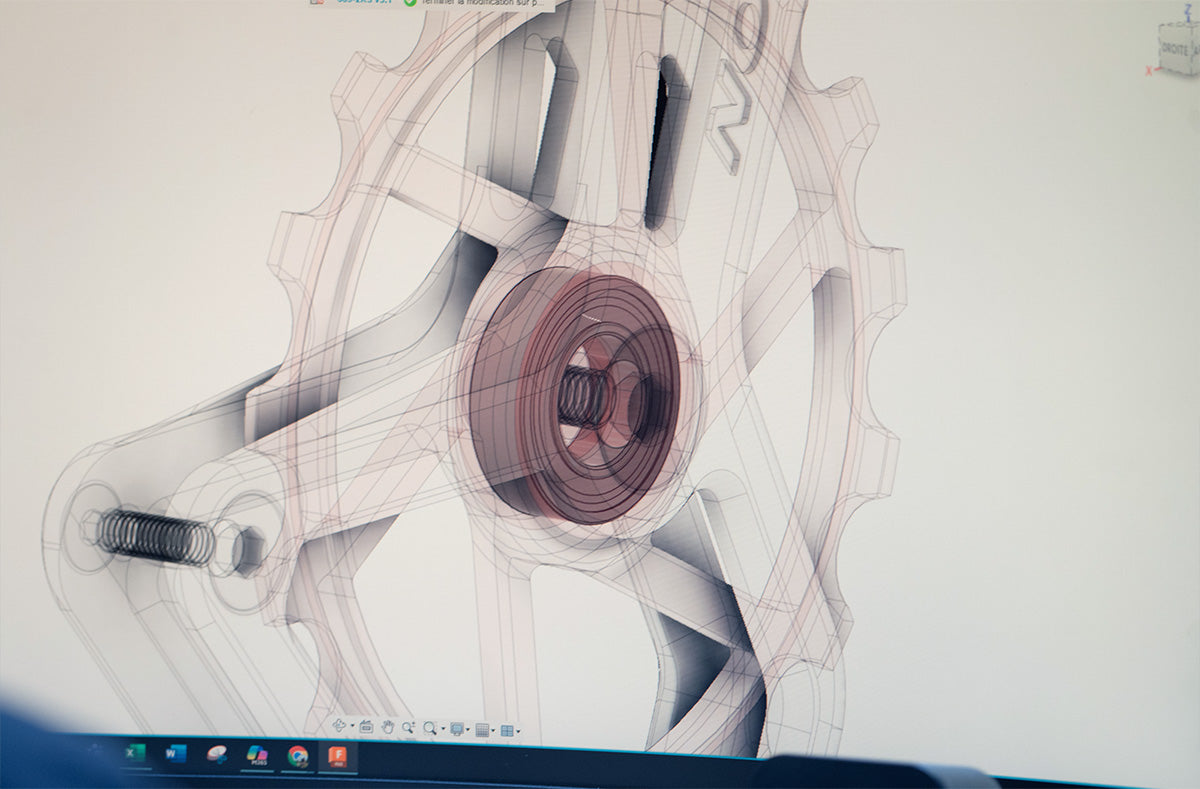

3D Modeling

The next step was to translate our initial vision into a tangible product to bring the concept to life.

This step allows us to visualize the product from all angles, refine its shape, optimize its ergonomics, and anticipate manufacturing challenges. Accurate modeling is essential to translate the vision into a foundation for the next steps.

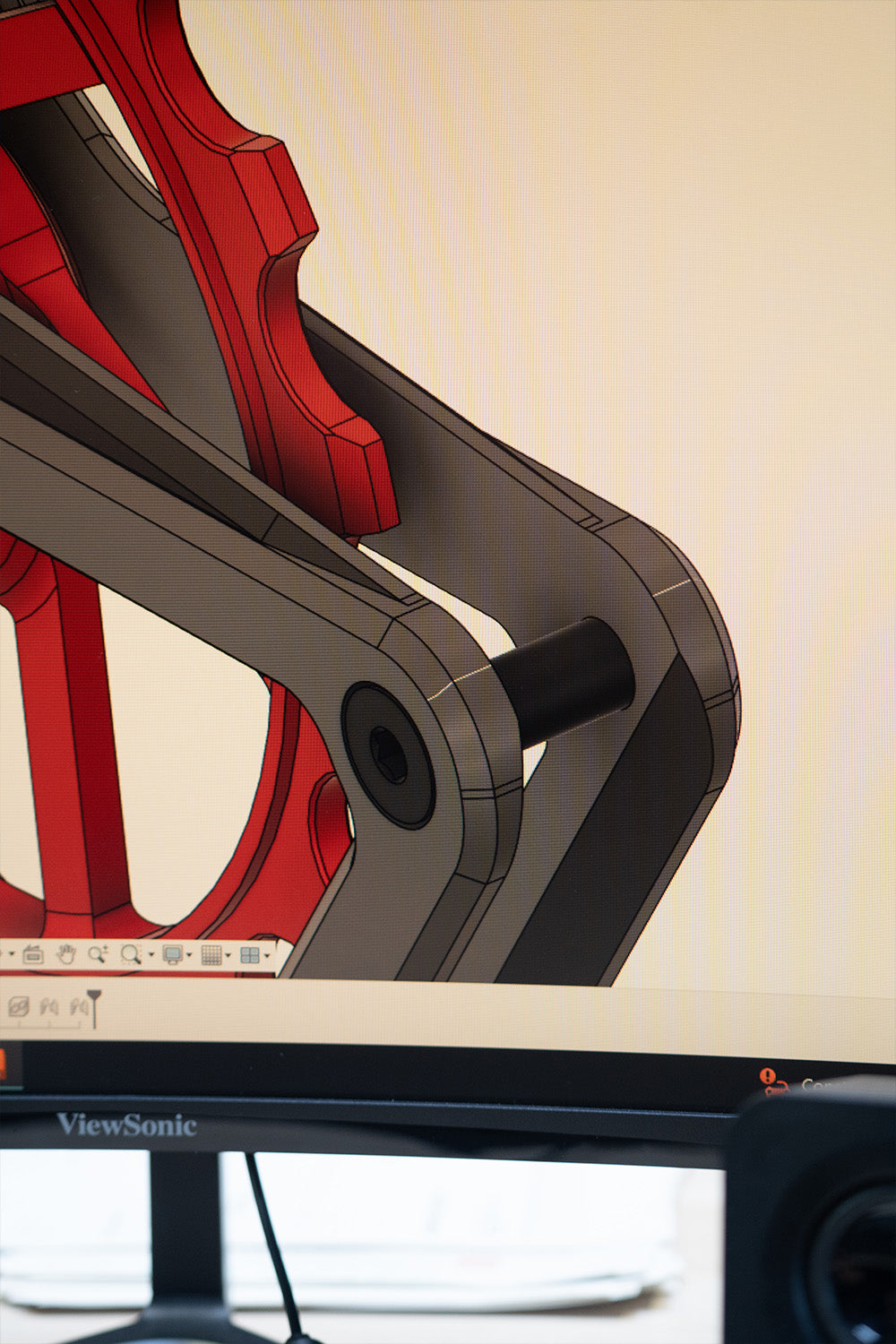

Iterate and prototype

This iteration phase is our favorite. It allows us to test different configurations, identify weak points, and make improvements accordingly.

Each prototype is a crucial learning curve as we work toward the optimal form and functionality.

Final testing and adjustments.

The final phase consisted of creating functional prototypes to conduct a series of real-world tests to assess durability, perceived quality, and compliance with our expectations.

Based on the feedback received, final adjustments were made to the final design, ensuring a finished product of impeccable quality and finish.

Features and new features

Every aspect has been meticulously studied.

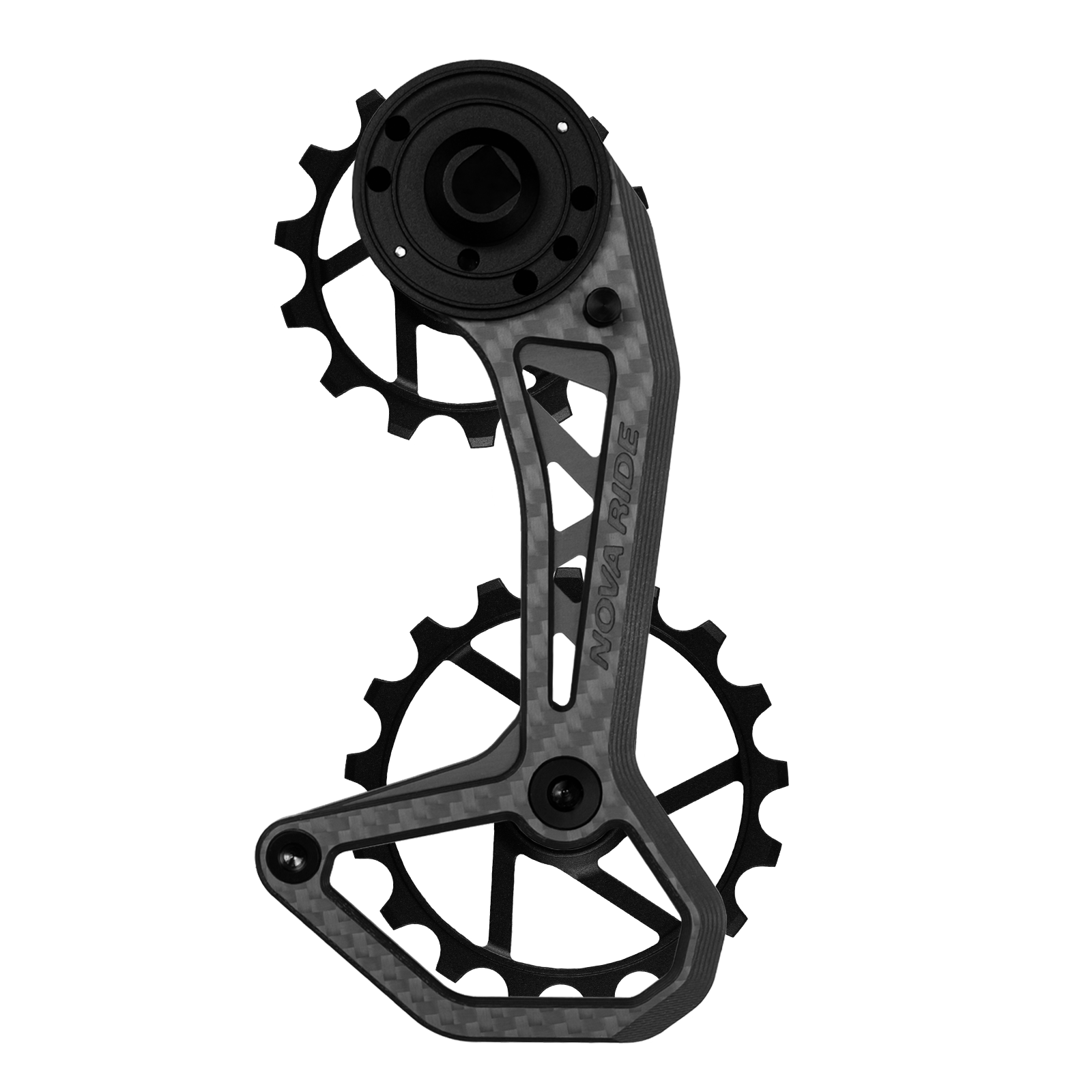

From the overall geometry to the optimized thickness of our ultra-light and strong 3K carbon fiber, including the teeth of the pulleys (for perfect chain retention and significant weight reduction) and the aerodynamic integration of the front screws, nothing has been left to chance. At the rear, titanium screws guarantee a perfect balance between lightness, robustness and aesthetics. The matte finish, obtained thanks to a protective varnish, gives a lasting elegance to the cage and its carbon fibers, while a strategically placed reinforcement at the rear reinforces the rigidity of the whole.

True to our values of performance, durability, and affordability, we've kept the tried-and-true materials of our original oversized derailleur cage: two 3k carbon plates and 7075 aluminum pulleys for optimal strength-to-weight ratio and crucial lightness. 100% ceramic dry bearings (cage and balls) for minimal friction, reduced maintenance, and maximum smoothness/performance, even in the most demanding conditions.

This part takes the same requirements for the operation of the bicycle derailleur and offers optimized drivetrain performance.

7 colors, double option

One focused on performance and lightness.

The other on aesthetics and customizing your bike.

Your CCD EVO, your choice.

From idea to reality

The CCD EVO represents the culmination of our know-how and results in an ultimate and detailed improvement for demanding cyclists, concerned with performance and a unique design.

Now available for the following derailleurs:

Shimano ULTEGRA / DURA-ACE and Sram RIVAL / FORCE / RED AXS, 12-speed.